Order Inquiry

ONIONS

They are sweet and they are red, they are unmatched in flavor and in taste.

Scroll down for Your Order Inquiry Form

They are sweet and they are red, they are unmatched in flavor and in taste.

Scroll down for Your Order Inquiry Form

Handpicked three times a year from the low altitude loam-rich clay soils of the valleys of the Oti River (Northern Togo) and the Senegal River (Senegal), where the Sweet Red Galmi has been planted, curated, and cultivated for over a century by men and women to whom the Galmi has become an identity-defining crop

Customer Ordering Inquiry

"*" indicates required fields

Ordering FAQ

The sweet red Galmi variety refers to a specific type of onion that originates from the village of Galmi in Niger, West Africa. It’s a short day onion, derived from the “Pink Maggia” variety, and marketed since 1975 under the “violet de Galmi” name in most of Western Africa and parts of Europe. The country of Niger was established trademark rights on the Galmi seed variety, on the basis of the specific regional origin classification under the World Food Organization (FAO) guidelines.

The Galmi variety has now been cultivated in the Tahoua Province of Niger (of which Galmi is a local settlement) for over 200 years, and it has been selectively bred since the early1970s by various university research centers,starting with Niger’s own IRAT in 1973.

Galmi onion has been cultivated and adapted to local conditions in the Sahel region, giving it distinct characteristics, such as its sweetness and ability to thrive in arid environments. This growing environment allows for incredibly long shelf-life of up to 7 months when properly stored.

The Galmi onion, originally from the village of Galmi in Niger, has gained popularity beyond its origin due to its sweet flavor and adaptability to semi-arid climates.

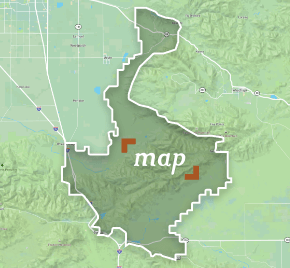

It’s the TAHOUA province in central Niger that is most commonly associated with the Galmi onion, especially the geographic area of the Ader-Doutchi-Maggia (ADM) highlands, where the Maggia Valley is located. That is where the Galmi hails from and where to this day more than 120,000 farmers make a living tending to Galmi onion fields from generation to generation.

While it is most closely associated with Niger, Galmi onions are also cultivated in several other neighboring countries, in West Africa with climate conditions similar to that of Central Niger, including Northern Togo (Mango River area and Bassar region), Northern Nigeria, Burkina Faso and most notably Senegal. ThiscoastalSahelian countryhas now developed a strong reputation for onion growing, thanks to suitable growing conditions,particularly in the arid and semi-arid northern portion of the country, an area known as the “Niayes”, along the Senegal River Basin.

The sweet red Galmi onion holds several unique advantages over other sweet onions, particularly when it comes to versatility, resilience, and cultural significance. Here’s why the Galmi onion can be considered “better” depending on the context:

Vibrant Appearance

- The Galmi onion’s reddish-purple outer skingives it a distinctive look that enhances visual appeal in dishes. This makes it especially valuable for chefs and food enthusiasts who want to add a splash of color to their meals.

Bold Yet Balanced Flavor

- While it retains a pleasant sweetness, the Galmi onion also has a slightly more robust flavorcompared to the ultra-mild yellow onions commonly found in North American markets from April to August. This makes it versatile in both raw applications and dishes that require bold flavors, such as stews, sauces, and South and West Asian curries and dishes.

Adaptability to Harsh Climates

- The Galmi onion is drought-resistant and thrives in semi-arid conditions, making it an ideal crop for regions with limited water resources. This resilience makes it a sustainable choice in a world increasingly affected by climate change.

- Sweet yellow onions in North American markets, on the other hand, require specific low-sulfur soils and controlled irrigation, limiting their cultivation to a very specific geographical area.They exhibit shorter shelf life, thanks to high water content, and can only be grown under specific growing conditions in one or two small areas.

Sustainability and Local Impact

- The cultivation of Galmi onions supports local farming communities in West Africa, contributing to economic development and food security in the region. Purchasing Galmi onions helps promote fair trade and the livelihoods of small-scale farmers.

- Sweet yellow onions, while an iconic U.S. product, are grown on a more industrialized scale, which may lack the direct social impact tied to Galmi production.

Longer Shelf Life

- Galmi onions are known for their better storage potential due to their adaptability to arid climates. This allows for a longer shelf life compared to their sweet yellow counterparts, which have a higher water content and are more perishable.

Global Culinary Appeal

- Galmi onions are deeply embedded in West African culinary traditions but have increasingly gained recognition in global cuisines due to their unique characteristics. Their bold flavor complements diverse recipes, from rich curries and stews to fusion dishes.

In Summary

The sweet red Galmi onion stands out for its stunning color, robust flavor, longer shelf life, and adaptability to challenging climates, making it a superior choice for sustainability-minded consumers and for chefs seeking a versatile and visually striking ingredient. While typical sweet yellow onions excel in mildness and sweetness, Galmi onions offer a broader range of applications and greater cultural and ecological significance.

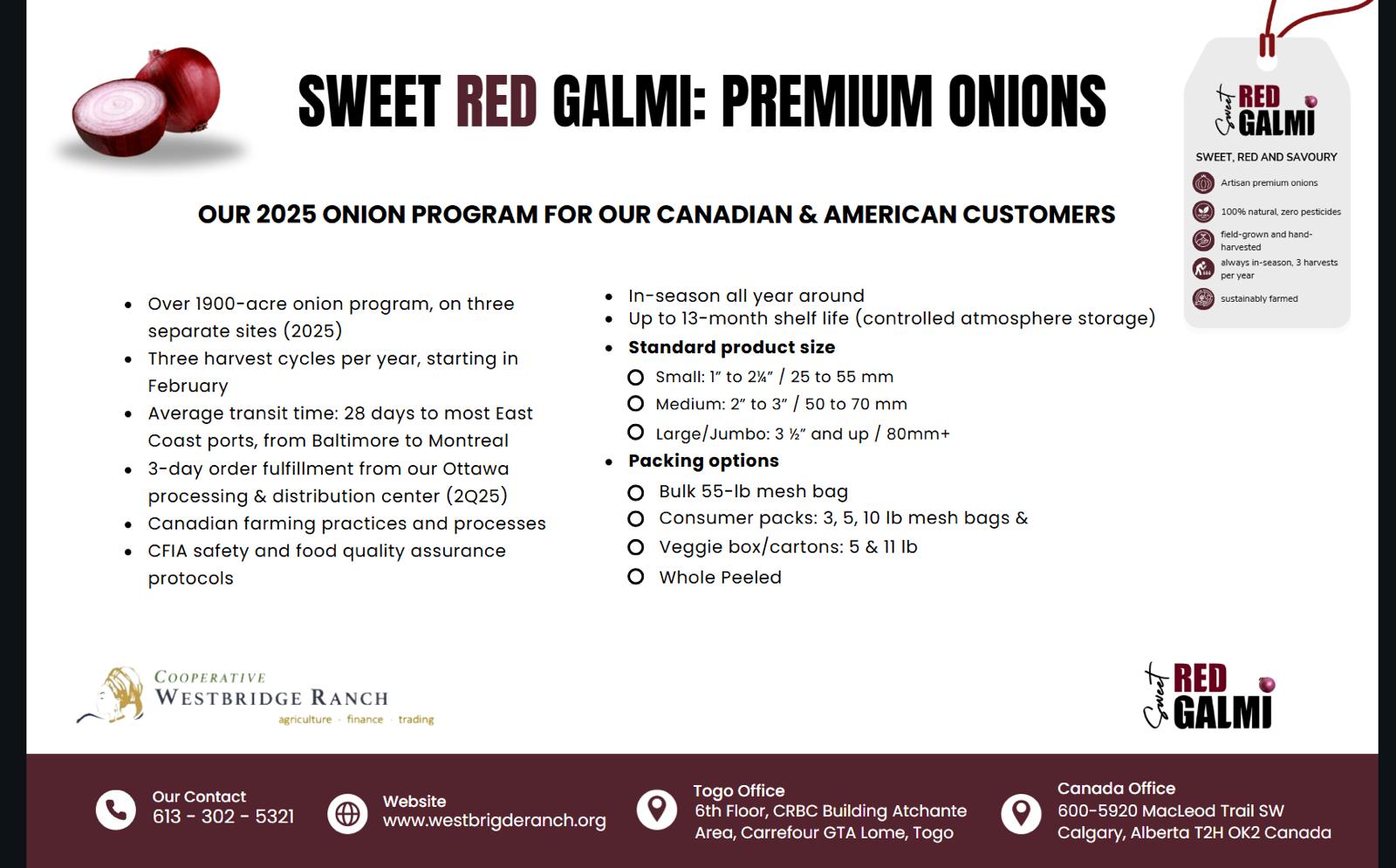

Our supply chain reflects our unwavering commitment to quality, safety, and reliability. From our farms in West Africa to markets across Canada and the US, we ensure every step of the process adheres to the highest standards.

We endeavor the take out most of the inventory and supply chain risk out of the equation for our buyers. From our diligent yet handcrafted harvesting, to local transport and shipping, every step of the supply chain processis designed to shorten the farm-to-shelf journey. And our Canadian storage and processing facility (Ottawa, ON) coming online early spring 2025 will help further our commitment to a 3-dayorder fulfillment promise to our customers. All year round.

Our premium sweet red Galmi onions, imported from our farms in West Africa, benefit from duty-free and tariff-free access under two key trade agreements: Canada’s Least Developed Country Tariff (LDCT) and the United States’ African Growth and Opportunity Act (AGOA). Here’s how each program works for your Canadian and U.S. markets:

- Canada: Least Developed Country Tariff (LDCT):

What it is: The LDCT is a preferential trade program established by Canada that eliminates import duties on most goods, including agricultural products, originating from Least Developed Countries (LDCs) as designated by the United Nations.

How it applies to our onions:

- Many countries in West Africa qualify as LDCs (e.g., Niger, Burkina Faso, Mali, Togo, Senegal).

- Onions imported from these countries are eligible for duty-free access to the Canadian market under the LDCT, provided they meet the program’s rules of origin requirements.

- These rules require that the onions be entirely grown and harvested in a qualifying LDC to be eligible.

2. United States: African Growth and Opportunity Act (AGOA)

- What it is:AGOA is a U.S. trade policy that provides duty-free access to eligible African countries for a wide range of products, including agricultural goods, as long as the products meet the rules of origin and other compliance requirements.

- How it applies to our onions:

- Many West African countries (e.g., Ghana, Senegal, and Niger) are AGOA beneficiaries.

- Our onions can be imported into the U.S.tariff-free if they are grown and harvested in AGOA-eligible countries and comply with AGOA’s origin requirements.

- This program encourages economic development in Africa by providing favorable access to the U.S. market for goods produced in participating countries.

3. Key Benefits of Canada: Least Developed Country Tariff (LDCT) &United States: African Growth and Opportunity Act (AGOA)

- Cost Efficiency:Duty-free imports reduce overall costs, allowing us to offer competitive pricing to Canadian and U.S. customers.

- Market Accessibility:These trade programs provide Westbridge with seamless access to two major markets, Canada and the U.S. Our vast land holdings and year-around focus on onions, with three harvests per year, help ensure a constant supply of product

Support for Sustainable Trade: These programs align with global efforts to support economic development in Least Developed Countries, which aligns with Westbridge’sethical and socially responsibilities.

Westbridge’s level of Canadian content is in fact, quitesignificant. Here’s a detailed breakdown of how Canadian content is determined in this context:

1. Ownership and Management (High Canadian Content)

- Our entire operations areCanadian-owned and managed, meaning we have Canadians on site, overseeing our operations in West Africa while the majority of our leadership team is based in Ottawa and Toronto.

- Key decisions, capital investments, and operational oversight are directed from Canada.

2. Processing in Ottawa, Ontario (Substantial Canadian Content)

- Starting in Q2 2025, our harvested and shipped onions will undergovalue-added processing in Canada, significantly increasing the Canadian content level:

- Labor:Employing Canadian workers for processing operations contributes directly to the Canadian economy.

- Facilities:The investment in infrastructure in Ottawa creates tangible assets on Canadian soil.

- Taxes:Processing activities generate local taxes, benefiting Canadian public services and infrastructure.

3. Supply Chain Integration (Moderate Canadian Content)

- We rely heavily on Canadian supply chains for our logistics, distribution, and marketing activities:

- Canadian transport networks and services are utlized to move processed onions to markets across Canada and the U.S.

- Canadian retailers and food service providers stock and promote our onions.

4. Market Focus (Moderate Canadian Content)

- By prioritizing Canadian markets (in addition to the U.S.), our operations align with domestic economic interests, serving Canadian consumers with a high quality product and contributing to food security.

5. Product Origin and Farming (Limited Canadian Content)

- While the farming itself takes place in West Africa, its connection to Canada is reflected through:

- Canadian expertise in farm management, technology, and sustainability practices.

- Ownership profits flowing back into Canada.

Overall Canadian Content Level

While our farming occurs outside of Canada, the processing in Ottawa, ownership structure, economic contributions, and market integration ensure that a significant portion of the value chain is Canadian.

Once the Ottawa processing facility comes online, our Canadian content will increase further, as the onions will undergo transformation and value addition within Canada before reaching consumers.

We currently operate a processing center on the outskirts of Lomé, Togo, where our premium onions are cleaned, sorted, and bulk bagged for export. This facility operates to Canadian standards with protocols and controls for sanitation, equipment maintenance and cleaning, environmental (temperature and humidity), employee training and recordkeeping. To better serve our growing customer base in North America, we are in the process of establishing a large storage and processing center in Ottawa, Ontario, which is expected to come online in Q2 of 2025. This new facility is designed to enhance our service offerings for customers in Ontario, Quebec, and the Northeastern United States by providing:

- Custom Bagging and Private Labeling: Tailored packaging solutions to meet specific customer requirements, including branding and product presentation.

- Expedited Delivery Services: Efficient distribution channels will enable overnight delivery and 1-3 business day deliveries, ensuring our customers receive fresh, high-quality onions promptly.

The Ottawa processing center will act as a hub for value-added services while streamlining logistics and reducing delivery times, reinforcing our commitment to delivering premium products with unmatched reliability and convenience.

The combination of favorable microclimates, vast land holdings, sustainable multi-harvest cycles per year, and advanced water resource management enables us to consistently produce at scale and to thus meet the demands of our customers in Canada, the United States, and beyond with fresh, high-quality onions throughout the year.

As a Canadian company operating in West Africa exporting to Canada and the United States, employing a robust and well-structured product recall strategy is essential to ensure compliance with regulations, maintain customer trust, and safeguard our brand reputation.

Our comprehensive recall plan has been tailored to the regulatory requirements of both Canada (Canadian Food Inspection Agency (CFIA) guidelines) and the U.S. (Food Safety Modernization Act (FSMA). Which includes detailed supply-chain traceability (batch coding and lot identification) software and actions plans to quickly isolate, remove and dispose of any affected products.

Westbridge Ranch sells primarily to grocery retailers, food wholesalers and food service providers. We do not sell directly to retail customers.

Higher yields on vast acreage, along with 3-harvest annual cycle combine to allow us to contemplate a 2025 production level of up to 54,000 metric tons. Including third-party production from our partner-cooperatives, our 2025-26 production capacity is expected to be around 83,000 metric tons.

As a proudly Canadian company, we are deeply committed to upholding Canadian standards for working conditions across all our operations, including our farms, processing facilities, and warehouses in West Africa. This commitment reflects our core values of respect, fairness, and sustainability, ensuring that our workforce benefits from safe, equitable, and ethical practices.

We not only enhance the lives of our employees in West Africa but also contribute to a globally responsible and ethically grounded supply chain, ensuring our customers can trust the integrity of our products.

Sustainable agriculture is central to our onion production, transportation, and processing, forming the foundation of our business model and ensuring that we produce high-quality onions while preserving the environment and supporting the well-being of our communities. Here’s how sustainability is integrated into each stage of our operations:

1. Sustainable Onion Production

- Crop Rotation and Soil Health:

Our significant land holdings in West Africa enable large-scalecrop rotation, which prevents soil depletion, minimizes the risk of pests and diseases, and ensures long-term fertility. This sustainable practice is crucial for maintaining high-quality onion yields. - Water Resource Management:

Careful management of water resources is essential in the tropical savanna climate where our farms are located. We employ:- Drip irrigation systemsto maximize water efficiency.

- Practices to prevent water wastage and salinization of soils.

- Organic and Natural Methods:

We prioritize the use of organic fertilizers and pest control methods, reducing reliance on synthetic chemicals that can harm the environment and biodiversity. - Climate Adaptation:

Our farming practices are designed to adapt to the challenges of climate change, ensuring resilient onion production through heat-tolerant crop varieties and precise planting schedules.

2. Sustainable Transportation

- Efficient Logistics:

We optimize transportation routes to reduce fuel consumption and emissions, ensuring that our onions travel from West Africa to markets in Canada and the U.S. with minimal environmental impact. - Low-Impact Packaging:

Our packaging solutions for bulk and retail products prioritize recyclable and biodegradable materials, reducing plastic waste and supporting a circular economy. - Local Processing for Export:

By cleaning, sorting, and bulk bagging our onions at our Lomé processing facility, we minimize unnecessary shipping of waste or non-consumable parts, lowering the carbon footprint of transportation.

3. Sustainable Processing

- Energy Efficiency:

Our upcoming processing center in Ottawa (Q2 2025) is being designed withenergy-efficient technologies, such as LED lighting, modern insulation, and renewable energy options, to minimize energy consumption. - Waste Reduction:

Both our West African and Canadian facilities prioritize minimizing waste. Unsellable onions or trimmings are used for composting or animal feed, creating a closed-loop system. - Custom Packaging Solutions:

By processing onions closer to the final market (e.g., custom bagging and private labeling in Ottawa), we reduce the environmental costs associated with repackaging and secondary transportation.

4. Community and Social Sustainability

- Supporting Local Communities:

Sustainable agriculture is not just about the environment—it’s also about people. We invest in the well-being of our farming and processing communities by:- Providing fair wages and safe working conditions.

- Offering training on sustainable farming techniques.

- Contributing to local infrastructure, such as access to clean water and education.

- Fair Trade Practices:

Our commitment to ethical sourcing ensures that our operations positively impact the communities in West Africa, aligning with global goals for equitable development.

Sustainability is not just a part of what we do—it’s at the core of our mission. By integrating sustainable agriculture into onion production, transportation, and processing, we are creating a resilient, eco-conscious, and socially responsible supply chain that serves our customers while preserving resources for future generations.

While our onions are not yet certified organic, we are actively working with EcoCert to certify several large tracts of our farmland. These fields are on track to achieve organic certification by late 2025, reflecting our commitment to meeting the highest standards of sustainable and organic agriculture.

In the meantime, we proudly practice natural methods of cultivation and pest control to ensure that our onions are grown responsibly and sustainably.

This transitional phase is an exciting step forward as we continue to enhance our sustainable practices. By late 2025, our certified organic onions will complement our existing premium offerings, meeting the growing demand for environmentally conscious and responsibly grown produce.

Our imported red onions do not cause job losses in the Canadian vegetable sector. Instead, they fill a vital gap in the market for a product that has historically been in short supply domestically. Canada has always been a net importer of red onions (as a country we in fact import over half of our annual onion consumption), and our operations complement our farmers’ work to address gaps in our country’s food supply chain and help meet the challenges of growing demand.

While, our bulk delivery service covers mostly CIF and FOB delivery Port of Montreal, we do provide Direct-to-Store-Delivery (DSD), through 3PL partners, in Montreal and in Ottawa. DSD is a key component of our private label partnerships with our customers. And we expect to expand the service to other large urban markets later in the year.

Westbridge Ranch will collaborate with retailers to provide private label programs.

Given the perishable nature of red onions, Westbridge focuses on streamlining the pallet-to-shelf transition and minimizing shrinkage through a well-coordinated approach across the supply chain. Here’s how we ensure efficiency and product quality:

1. Cold Chain Management

- Temperature-Controlled Environments:

We maintain optimal storage and transportation temperatures from the moment onions are harvested to their arrival at retail locations. This is achieved through:- Temperature-controlled warehouses.

- Refrigerated trucks or containers during transit.

- Monitoring Systems:

We utilize IoT-enabled temperature and humidity monitoring systems to track conditions in real time, ensuring consistent quality.

2. Just-in-Time Delivery

- Demand Forecasting:

Through advanced analytics we can predict demand accurately, ensuring only the required quantity of onions is shipped to retailers, reducing overstock and waste. - Efficient Scheduling:

We optimize delivery schedules to minimize storage times at distribution centers and warehouses, reducing the risk of spoilage.

3. Streamlined Processing and Packaging

- Processing Centers Near Markets:

Facilities like our upcoming Ottawa processing center to clean, sort, and pack onions closer to end markets. This reduces transit times and ensures the product is market-ready upon arrival. - Shrink-Reducing Packaging:

Using breathable, moisture-resistant packaging we are able to extend the onions’ shelf life. - Custom Labeling and Sorting:

We tailor bulk and/or retail package to specific retailer needs, enabling faster shelf placement.

4. Supply Chain Coordination

- Collaborative Partnerships:

By work closely with our retailers and distributors we align on inventory needs, ensuring efficient pallet-to-shelf transitions. - Retailer Training:

In some cases we provide guidelines for retailers on handling, storage, and display practices to minimize shrinkage once products arrive at stores.

5. Quality Assurance Systems

- Grading and Sorting:

By implementing rigorous quality checks at the farm and processing stages we ensure only high-grade onions reach the market. - First-In-First-Out (FIFO):

We utilize FIFO inventory management to prioritize the sale of older stock, reducing spoilage.

6. Retail Support Services

- Expedited Deliveries:

We offer services like overnight or 1–3 business day deliveries for retailers in Ontario, Quebec, and the Northeastern U.S., minimizing the time onions spend in transit or storage. - Shelf-Ready Packaging:

Provide packaging designed for immediate placement on store shelves, reducing handling by retail staff.

7. Sustainability Practices

- Composting and Secondary Markets:

We divert onions that don’t meet retail standards to composting or secondary markets, such as food processors or animal feed producers, to reduce waste. - Educating Retailers and Consumers:

By promoting best practices for storage and usage we are able to extend the product’s life after purchase.

At Westbridge Ranch, we take food safety and traceability very seriously, and our Traceability & Food Safety Program has been meticulously designed to meet and exceed the requirements of the Canadian Food Inspection Agency (CFIA).

- Key Features of Our Traceability & Food Safety Program:

- Compliance with CFIA Standards

- Comprehensive Tracking Systems

- Regular Audits and Assessments

- Our Commitment to Innovation and Continuous Improvement:

- Adopting New Technologies

- Adopting Enhanced Software Systems

- Modern Equipment Integration

Benefits of Our Program for Customers:

- Rapid Recall Capability

- Transparency and Trust

- Global Best Practices

At Westbridge Ranch, food safety is not a one-time achievement but an ongoing responsibility. By combining our deep understanding of regulatory requirements with a proactive approach to innovation, we ensure that our Traceability & Food Safety Program remains a cornerstone of our operations.

CONTACT US

Togo Office:

6th Floor, CRBC Building Atchante Area, Carrefour GTA Lomé, Togo

Canada Office:

600 – 5920 MacLeod Trail SW, Calgary, Alberta T2H 0K2 (Canada)